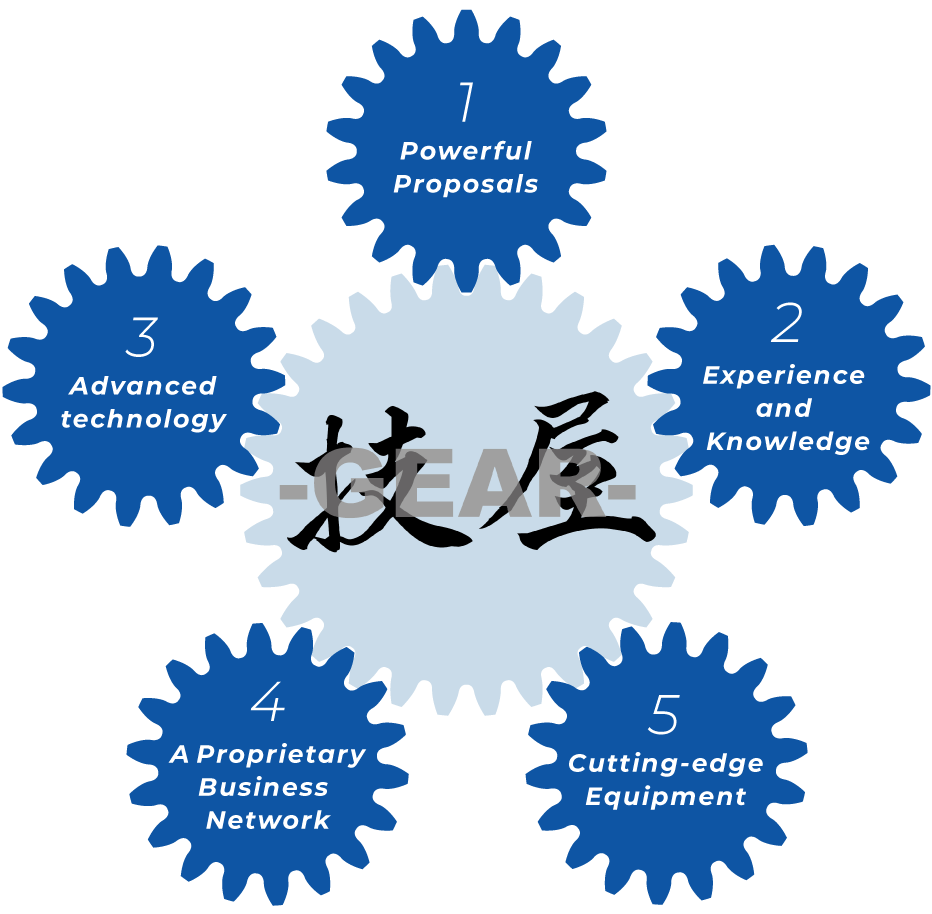

We will take on any request from our customers and will strive to meet it through our extensive knowledge and proven technology. Even if your request was turned down by other companies, we will take approaches from many different angles to provide a suitable proposal. We are always aiming to provide the best and will not shy from new challenges for ensuring that the customer is ultimately satisfied.

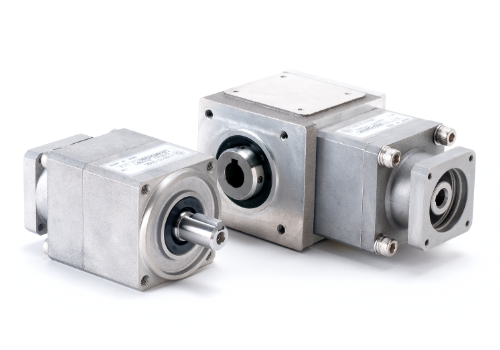

We make the most of our proven experience and knowledge in gear cutting and gear reducer designing and manufacturing acquired for more than half a century to provide original gear reducers to meet your needs.

Our design is compatible with servo motors from any manufacturer. Please feel free to choose what best suits your needs.

Any mounting position is possible due to the enclosed design.

Designers have freedom of choice due to the maintenance-free structure.

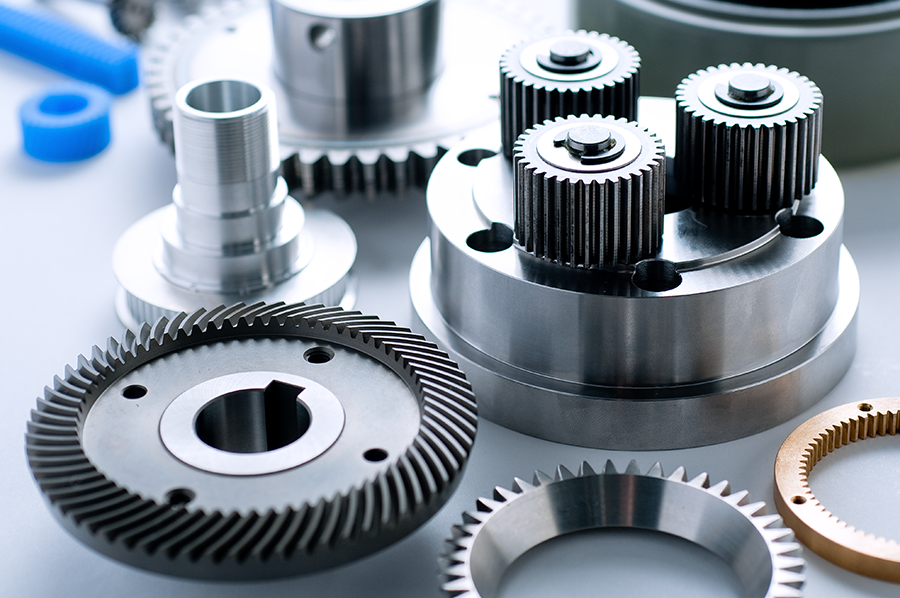

Founded as a gear manufacturer, we have leveraged our proven technology, honed over decades, to machine and assemble a wide array of precision parts. Through Value Engineering (VE) and Value Analysis (VA) proposals, we cater to the diverse needs of our customers.

We work with a broad spectrum of materials, from common metals (ferrous and nonferrous) to castings, forgings, sintered components, metal sheets, stamped parts, and more.

To streamline processes and reduce costs, we have established a network of supplier factories that enables us to provide a fully integrated system, from material procurement through heat treatment, surface treatment, machining, and assembly.

Various castings

Various alloy castings

Various forgings

Various die castings

Lost wax precision castings

Various sintered parts, MIM parts

Various metal plates

Various pressed parts

Various plastic parts

Various rubber parts

By leveraging a comprehensive suite of cutting-edge machinery and combining the sophisticated skills and expertise of our workforce, we strive to achieve higher machining efficiency and superior quality.

We possess a diverse inventory of machine tools, enabling us to manufacture a wide range of precision parts. Furthermore, we are continually expanding our inspection capabilities with a particular focus on 3D measuring instruments and gear testers.

If you have any questions about our products, discussions,

or problems that we can help you solve, please feel free to contact us at Sakanishi Seiki.